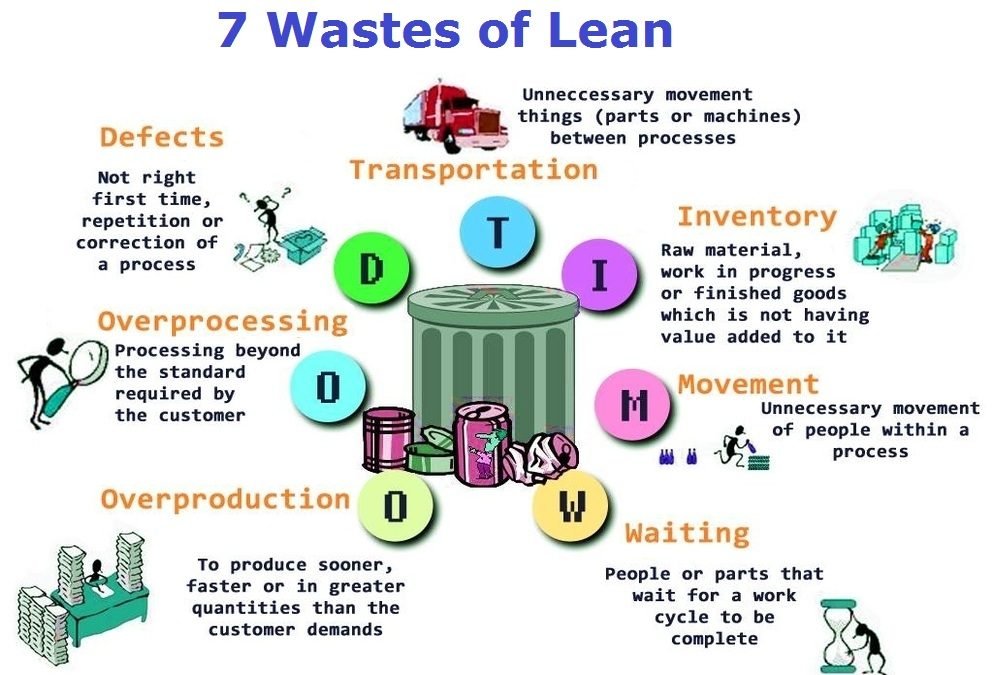

7 Waste Wonders or TIMWOOD

- June 21, 2019

- Posted by: Shafqat Jilani

- Categories: Business Consulting, Business plans, Business Troubleshooting, Finance & accounting, Human Resource, Innovation, SME, Training and Development

Causing your business a lot of damages

Business globally shares one thing in common, all are meant for profit, and all aim at increasing profits and reducing costs. Different businesses adopt different ways of reducing costs and most of these forget an in-house readily available cost-saving factor in the form of multiple wastes existing around the production, storage, procurement, management, supply chain, and sales function of the business. These wastes are often neglected and undervalued by the business managers unaware of the impact of these wastes they continue working on their well-practiced way of production and doing business resulting in adding more waste and more damage to the business. Manufacturing wastes or more precisely business wastes are grouped in seven types known as ‘7 Wastes of Lean Manufacturing’ or ‘TIMWOOD’.

- Transport

- Inventory

- Motion

- Waiting

- Overproduction

- Over Processing

- Defects

Transportation

Refers to the wastage of time, money, and efforts due to transportation as transportation may cause damage to the product, it may be lost or reduce its efficacy, proficiency, or utility during the transportation. It also adds to the cost leading to lower profits and sometimes losses. Unnecessary, prolonged, unreliable, and inappropriate transportation of raw materials and the finished product may add unwanted costs to production.

Inventory

Inventory either raw material or a work-in-progress (WIP) needs careful handling, storage, processing, recording, re-ordering, and management or the production will get affected by an increase in the cost of inventory due to direct or indirect lack of control. Ineffective or poor inventory management is another source of production losses and cost increases.

Motion

Any movement and work-related losses and damages either to the machines or people refer to the motion waste in the lean production process. Any careless handling of material, machine, tools, or equipment of one-self may cause motion damage or waste causing a lot of unrest and heavy cause to the business.

Waiting

When goods and materials are not moving into manufacturing or not being transported for sales, distribution, or further processing these are considered in ‘waiting’. When it comes to the idle state of the material or work-in-progress the extra cost is paid by the manufacturer leading to an additional burden on the company and the customer in the shape of the increased price.

Over Processing

Overwork, overcooking and overworking the complete product by repeating the process is another sort of wastage many manufacturing concern face in the absence of careful manufacturing techniques. Overdoing does not good for the product or the business.

Over Production

The value of production and its profitability converts into increased costs if it is done more than what was required. Considering warehousing and inventory management costs, overproduction ranks higher among manufacturing wastes and becomes lethal if the stored products deteriorate or lose their value in the delay of the process.

Defects

A multilayered loss to the business is caused by this very common waste in the production process. A defect in the product causes the waste of all production factors including raw material, time, energy, and effort. Rework is needed for the defective products that further multiply the manufacturing costs and adds to the process and production wastes.